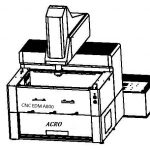

A-800

Users can use a rich database to input electrode-workpiece material, electrode scaling, electrode projection area machining depth, and final finish surface roughness according to requirements.

The system can automatically determine the machining program, segment the machining and automatically allocate the amount of pulsation until the final machining is completed.

AUTO processing without the need of operation skills, through a simple dialogue input, help, even inexperienced novices can quickly get started, to make the machine performance.

Touch screen input, handwriting box input operation, and other functions make the operation more convenient.

Support remote operation

- SUBSTANITAL DATABASE

- HIGH EFFICIENCY , GOOD QUALITY

- STABLE MACHINING FROM SHALLOW TO DEEP

- HIGH SPEED MACHINING ESPECIALLY RIB

|

Item |

Unit |

A-800 |

|

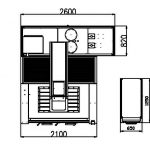

Worktable size (L*W) |

mm |

1050 x 600 |

|

Liquid tank internal size(L XW XH) |

mm |

1680 x 1100 x 600 |

|

X 、y 、Z axis travel |

mm |

800 x 500 x 400 |

|

Max.electrode weight |

kg |

150 |

|

Max.Workpiece size |

mm |

1500 x 1000 x 550 |

|

Max.Workpiece weight |

kg |

4000 |

|

MIN.AND MAX.DISTANCE WORK SURFACE TO ELECTRODE PLATE |

mm |

500 / 900 |

|

POSITIONING ACCURACY (JIS STANDARD) |

|

6μM / L(ARBITRARILY)300 mm |

|

REPEAT ACCURACY (JIS STANDARD) |

μM |

3 |

|

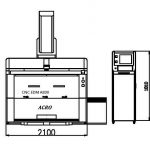

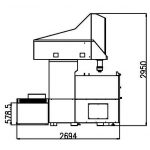

Overall size(L XWXH) |

mm |

2800 X 2700 X 2900 |

|

Machine weight(EXCLUDING DIGITAL POWER) |

kg |

5000 |

|

Processing liquid filter type |

|

Exchange type cartridge Filter |

|

Max.Current |

A |

50 |

|

Total Input power |

KVA |

9 |

|

Input VOLTAGE |

|

220V / 380V / 415V |

|

Best surface roughness |

Ra |

RaO.2μm |

|

Min. Electrode wear |

|

0.1% |